Liquid Products

Gel & Liquid Pouch Product Fill & Seal Packaging Equipment

Matrix Packaging Machinery has proven itself as the leader of vertical form fill seal systems. Delivering rugged, easy to use packaging machinery to multiple industries offering customers high quality packaging solutions that last.

Packaging liquids can be a challenging endeavor if your packaging team does not have the experience necessary to understand your filling system and how it relates to your packaging machine, Matrix partners with their customers to talk through options and what configurations work best.

The Matrix Mercury is a reliable, consistent packaging machine that can fill liquids in a pillow bag from a minimum of 2" x 3". The mercury offers, speed and performance in an easy to use automated packaging machine. The small footprint provides flexibility in facility space. This vertical bagger also offers self-centering film drive down system automatic edge guide film tracking, as short travel film unwind system and angled incline film upwind. All contribute to precise film movements and trouble-free operation.

The Matrix Mercury comes with a variety of options, including tear notch, hole punch, gas flush systems, washdown, and more.

Matrix understand how to package liquids and pasty products and has worked with many applications such as; drinking water, soaps, gels, freezer pack gels, condiments, cosmetics, oils, and more.

INVpack is a leading provider of stickpack and sachet system for flexible packaging applications. As the first form fill seal company to specialize in stickpack format, the experience and knowledge that INVpack adds is unparalleled. Matrix is glad to partner with INVpack to provide customers with leading technology that continually evolves to follow the most rigorous security and hygienic rules, including Ultra Clean Format.

One of the most difficult packaging jobs is filling sachets with thick liquids at a high speed without sacrificing precision and efficiency. To assist manufacturers in this tedious process, INVpack offers the MVA series. This machine combines continuous film motion with an intermittent sealing process and seals packets on all four sides, preserving the integrity of the product.

Packaging liquids like dressings, oils, sauces or more requires a high-quality seal to ensure that products are ready for shipping and distribution. With innovation and advanced technology, the MVA high speed sachet system and the SP multilane stickpack series provide customers that are packaging liquids with machines that are well designed for this application.

For some customers filling liquids (including drinking water packaging) or pasty products, INVpack machines are the perfect solution. Features on the MVA series include high production outputs, a combination of continuous technology and intermittent seal processes, and the use of films up to 100 microns thick. The MVA series produces four-side seal sachets. Benefits of utilizing this INVpack machine in the liquids industry include high speed, high quality, precision, and efficiency.

Additional benefits on the MVA include options for 1-15 lanes, continuous motion speeds up to 70 cycles per minute per lane, and a capacity to produce up to 1050 sachets per minute.

The SP series offers 6 - 20 lanes, continuous motion speeds up to 70 cycles per minute per lane, producing on average 420 - 1400 stickpacks per minute.

The MVA and SP series have laser tear notch options, simplistic filling systems, regular or ultraclean options, and offers a small footprint, providing a valuable space saving benefit.

Other advantages to using the high speed sachet system include fast changeovers and high quality seals at a high speed. This machine uses the latest motion control technology to ensure speed, accuracy, and quality packaging sachets of salad dressings, pasty liquids, and other condiments.

Matrix is also the master distributor of the Pacraft line of pre-made pouch machines. So, if you are looking to fill liquids in a pre-made pouch the Pacraft line is one to review. These machines are rotary in nature, offering a small footprint. The easy cleaning wash-down designs offer intuitive operation, touch screen controls and can fill and seal a variety of products.

Depending on applications and production needs, Matrix can provide the best solution ensuring successful product packaging.

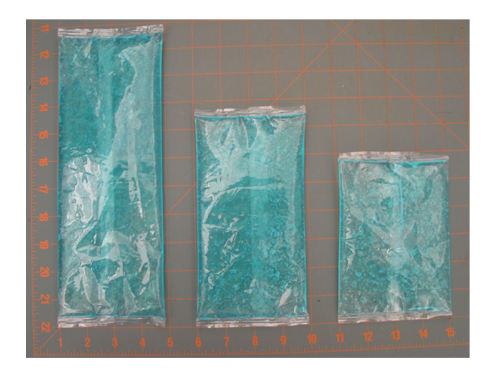

Matrix machine fill 5# of liquid freezer gel in large 8"x12" poly film pillow bags.

&t=9s